|

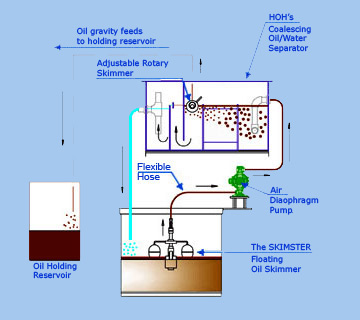

Typical Setup

The SKIMSTER® is attached to a 1/2" air diaphragm pump by a 3/4" hose, the suction from the pump and floating skimmer pulls the oil/water mixture into the intake of the skimmer, then to a Oil/Water Separator where the oil is removed from the wastewater and stored for recycling. The water is sent back to the storage tank or sent directly to the Sewer. (Check with your local Pretreatment Coordinator / Municipality for effluent limits and guidelines before you discharge wastewater.)

Shown is the OWS 5 Package System.

We offer package systems with capacity up to 300 gpm. Contact us with your requirements and we will configure an OWS Package System for your needs.

The SKIMSTER® Floating Oil Skimmer will remove free and dispersed surface oil from wastewater. It works on the principle of a controlled buoyancy weir coupled with a floating slide valve to effectively remove oil or other light liquid from the surface of the water. The pulsing action from the diaphragm pump brings the oily wastewater mixture to the SKIMSTER for efficient/effective removal.

The SKIMSTER® also has the ability to move to different locations.

More information on The SKIMSTER®

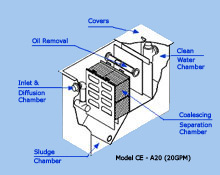

Oil/Water Separator

Featuring HOH's patented "CUBE" Coalescing Media

HOH's Cube Series Oil/Water Separators are of a gravity and coalescing design for removal of finely dispersed oil droplets from various petroleum waste streams. The use of "The Cube®" patented perforated coalescing media provides for predictable oil removal through impingement coalescence while allowing solids to drop off into a separate chamber.

HOH offers packaged systems up to 300 gpm.

Contact us with your requirements and we will configure an OWS Package System for your needs.

Home ::

Company ::

Oil/Water Separators ::

The SKIMSTER® Floating Oil Skimmer

Industrial Wastewater Treatment Equipment ::

Soil Vapor Extraction Systems

Liquid Handling Equip. & Replacement Parts ::

Wastewater Treatment/Solidification Program

Product Destruction Services ::

Contact Us

|